Weiss back in Scotland

Weiss back in Scotland

We have been working for the NHS at Raigmore Hospital in Inverness for the past few years, where we have installed two 1.6 MW biomass pellet boilers that produce steam for the hospital’s laundry/cleaning facilities.

We have been working for the NHS at Raigmore Hospital in Inverness for the past few years, where we have installed two 1.6 MW biomass pellet boilers that produce steam for the hospital’s laundry/cleaning facilities.

Our Service Engineer is currently there to provide support and training to their operating staff.

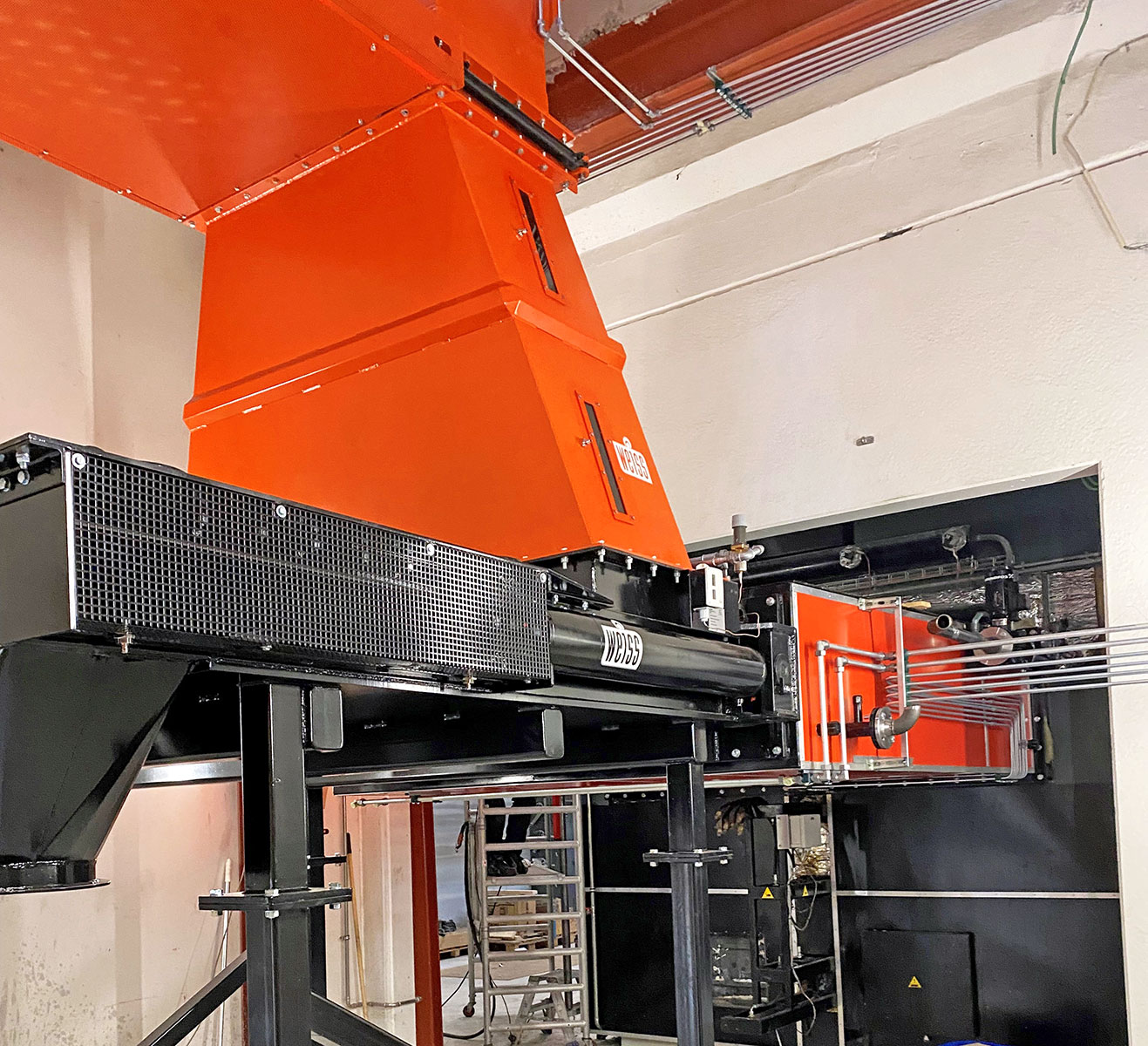

Production is in full swing at Weiss ApS

Production is in full swing at Weiss ApS

We are currently working on the production of a pusher piston for a Weiss wood chip pusher, which will be delivered and installed at Ølgod Varmeforsyning.

Customer on Bornholm gets new Weiss infeed system

Customer on Bornholm gets new Weiss infeed system

We are in the process of replacing the feed system on a wood chip fired non Weiss boiler for a customer on Bornholm.

Tasks consist of delivering, installing and commissioning a complete new Weiss system, consisting of:

- New double receiving hopper.

- New dosing tank with fire damper.

- New hydraulic pusher.

- New water-cooled duct.

Start-up of the system is scheduled for early November 2022.

First fire

First fire

Weiss is now finishing updating an older steam boiler with original retort principle at a customer on Funen.

It has been a major upgrade project where we have installed:

- A new complete Weiss stoker w/cell sluice.

- A new Weiss 1000 KW push grate for wood pellets w/hydraulic station.

- A transition section from grate to boiler.

- A new option for better air control, new primary/secondary fans.

- New ash augers.

The parts have been produced in Linkas Produktion in Lem, based on Weiss technology and know-how.

There was a First Fire on Wednesday, September 29th and now a little trimming and test drive is needed. It is really well done by all involved.

Custom designed ECO tops for Norway

Custom designed ECO tops for Norway

The 2 specially designed ECO tops with built-in gunshot cleaner are ready for shipment to Norway.

The customer wanted a more innovative solution that minimizes the risk of leaks and makes ongoing maintenance easier and more time-saving.

We at Weiss look forward to the customer getting this solution installed and tested and look forward to further deliveries of this innovative design/solution.

News from the Field Team

News from the Field Team

Our Field Team is finishing the Plant upgrade, servicing and repair of the Waste Incinerator in Greenland, so it is now in tip-top condition and ready for the Arctic winter.

The final details are finalized and the team continues back to the Netherlands for a major service assignment over the summer holidays on 2 x 11 MW biomass energy plants.

One of the appreciations we get from customers is the great flexibility in services over a summer vacation when most others are on vacation.

Working at full speed in Weiss

Working at full speed in Weiss

We have just started a major audit for a great customer in the Netherlands:

- Replacement of stainless steel Quench pipes.

- Repair of bag filter.

- Replacement of damper in ECO.

- Repair of the grate

We expect to be finished by the end of November.

Original Weiss shaker plates and spare parts

Original Weiss shaker plates and spare parts

Weiss OEM suppliers are selected according to various criteria. Among other things, they must be certified to ISO 9001 and ISO 14001. Using certified suppliers ensures that production is in order, that raw materials (radioactive, otherwise contaminated, different contents) and production are controlled.

The casting is tested with a spectrometer twice before it is released. What is the distance from the casting to the model? Is cooling under control? Post-processing, etc.

In addition to the chemical composition, mechanical durability is extremely important. DIN-compliant materials are used, so the tensile strength and working temperature range are strictly defined.