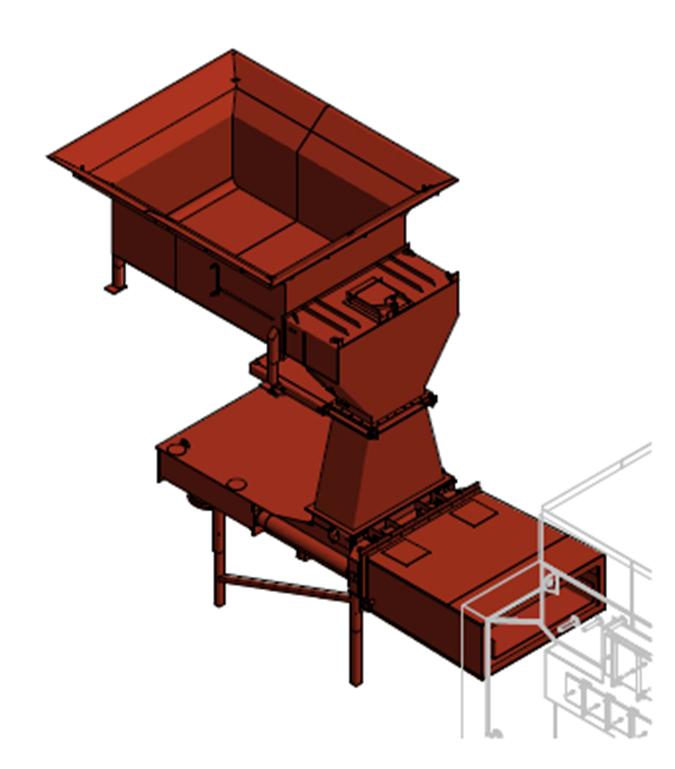

Complete wood chip framing system

Single hopper for receiving wood chips, with hydraulic discharge at the bottom, for dosing hopper. Also available as a double funnel.

Hydraulically operated fire damper equipped with an accumulator, which ensures that the damper also shuts off in the event of a power failure.

The dosing tank is equipped with an infrared level control and an automatic sprinkler system that is activated if the temperature in the dosing tank becomes too high, e.g. due to fire.

Hydraulically driven pusher, which pushes the material from the dosing hopper through the water-cooled channel into the boiler box. The pusher runs in step or frequency controlled mode, the size of which depends on the boiler load, ensuring a completely even feeding of the fuel.

Water-cooled duct to ensure a "chip plug" between the pusher and the combustion grate, thus preventing false air intake.

The water-cooled duct ensures that the system can withstand a backfire without risk of breakdown. At the transition from the water-cooled duct to the pusher, a number of fire nozzles are placed to further protect against backfire.

The duct is built and secured according to the pressure/temperature of the boiler and is connected directly to the boiler circuit.