FLUE GAS SCRUBBERS

The purpose of the flue gas scrubber is to use the heat/energy in the flue gas to heat the return water to the boiler, thus improving the efficiency of the boiler plant.

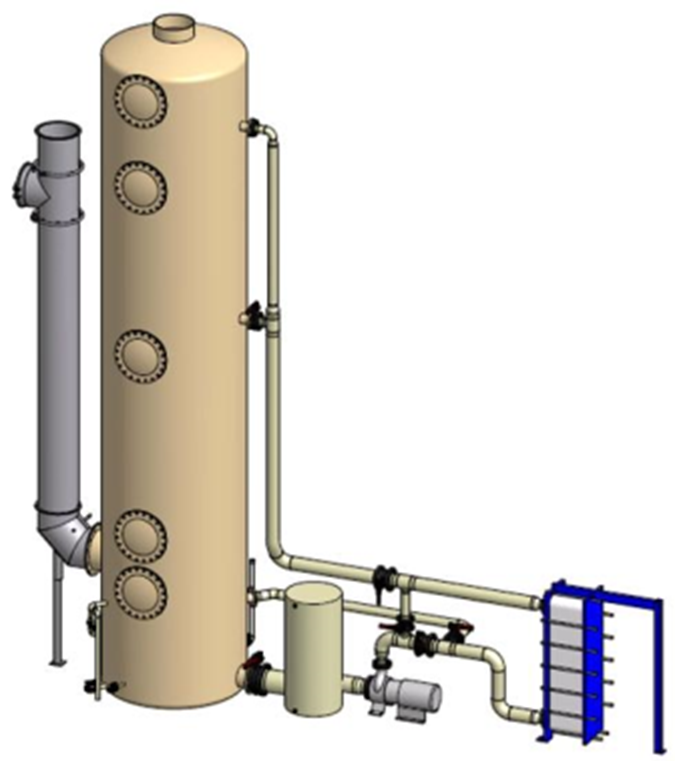

The purpose of the Quinch pipe is to lower the temperature of the flue gas. The temperature of the flue gas must be sufficiently low so that flue gas from the boiler condenses. The washing tower can be damaged if the flue gas temperature is too high. At the top of the quinch pipe are condensing nozzles that cool the flue gas. There are also emergency cooling nozzles that open if the condensing nozzles do not cool sufficiently. The emergency cooling nozzles also open if the water level drops in the washing tower. At the bottom of the quinch pipe are two temperature transmitters that control the temperature to the washing tower.

From the quinch pipe, the flue gas is led up through the washing tower. The scrubbing tower contains tetrahedrons (small plastic balls), condensing nozzles that spray on the flue gas, which cools and cleans the flue gas. The top nozzle in the washing tower is a large nozzle. Bottom nozzles are small nozzles. The tents are made of plastic and cannot withstand high temperatures. After the nozzles, the flue gas passes through a droplet trap which removes entrained water droplets. On the side of the washing tower is the water level glass, where the water level can be checked. The level in the wash tower is also controlled by a level transmitter. When the level rises, a valve opens to drain condensate. The condensate can be discharged to sewer, chip filter or belt filter.

Before the wash pump there is a coarse filter, The coarse filter traps large particles that would otherwise clog the nozzles in the quinch pipe and the wash tower. The scrubber pump must keep the pressure on the nozzles so that the flue gas scrubbing works in the most optimal way. The washing pump is frequency controlled and varies in speed. The speed is calculated from the PLC/SRO control. The flue gas temperature when leaving the scrubber tower must be low in order to get the best efficiency of the boiler system.

The wash water contains flue gas particles and has a pH value of about 3-4. To compensate for this, NaOH (lye) is added. The wash water must have a pH value of 7. It can then be discharged as condensate to the sewer, chip filter or belt filter.

The heat exchanger alternates wash water and return water to the boiler. Pressure transmitters are provided on both sides of the heat exchanger. The pressure transmitter is used to check if the pressure has changed. If the differential pressure between the forward and return pressure of the wash water increases, there is a need for backwashing of the heat exchanger. In the heat exchanger, particles from the wash water can settle and heat transfer is impaired due to deposits.